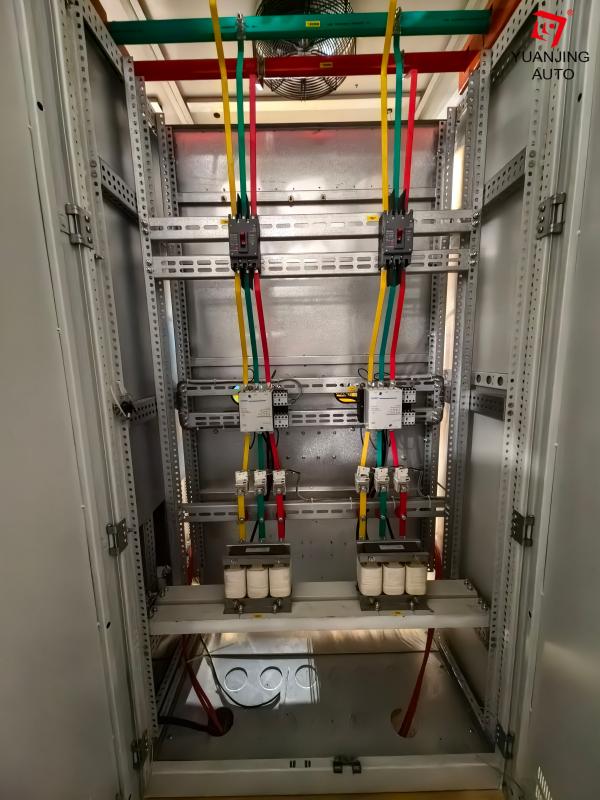

We offer customized Slitting Machine Unit solutions for various metal processing needs. Our slitting machine and machine slitter are built for accuracy, efficiency, and low maintenance.

Stainless Steel Coil Slitter Rewinder Lines