Galvanization Production Line

(Total 10 Products)

-

Innovations in Continuous Galvanizing Lines

Contact Now

-

Continuous Hot Dip Galvanization Production Line

Contact Now

-

Automatic Continous Zinc Steel Galvanization Production Line

Contact Now

-

Steel Hot Dipped Zinc Galvanization Production Line

Contact Now

-

Continuous Galvanization Production Line for Hot Dip Steel

Contact Now

-

Automatic Steel Galvanization Production Line

Contact Now

-

-

Steel Coil Hot Galvanization Production Line

Contact Now

-

Automatic Continous Zinc Plating Galvanization Line

Contact Now

-

-

Min. Order:1 Set/Sets

Transportation:Ocean

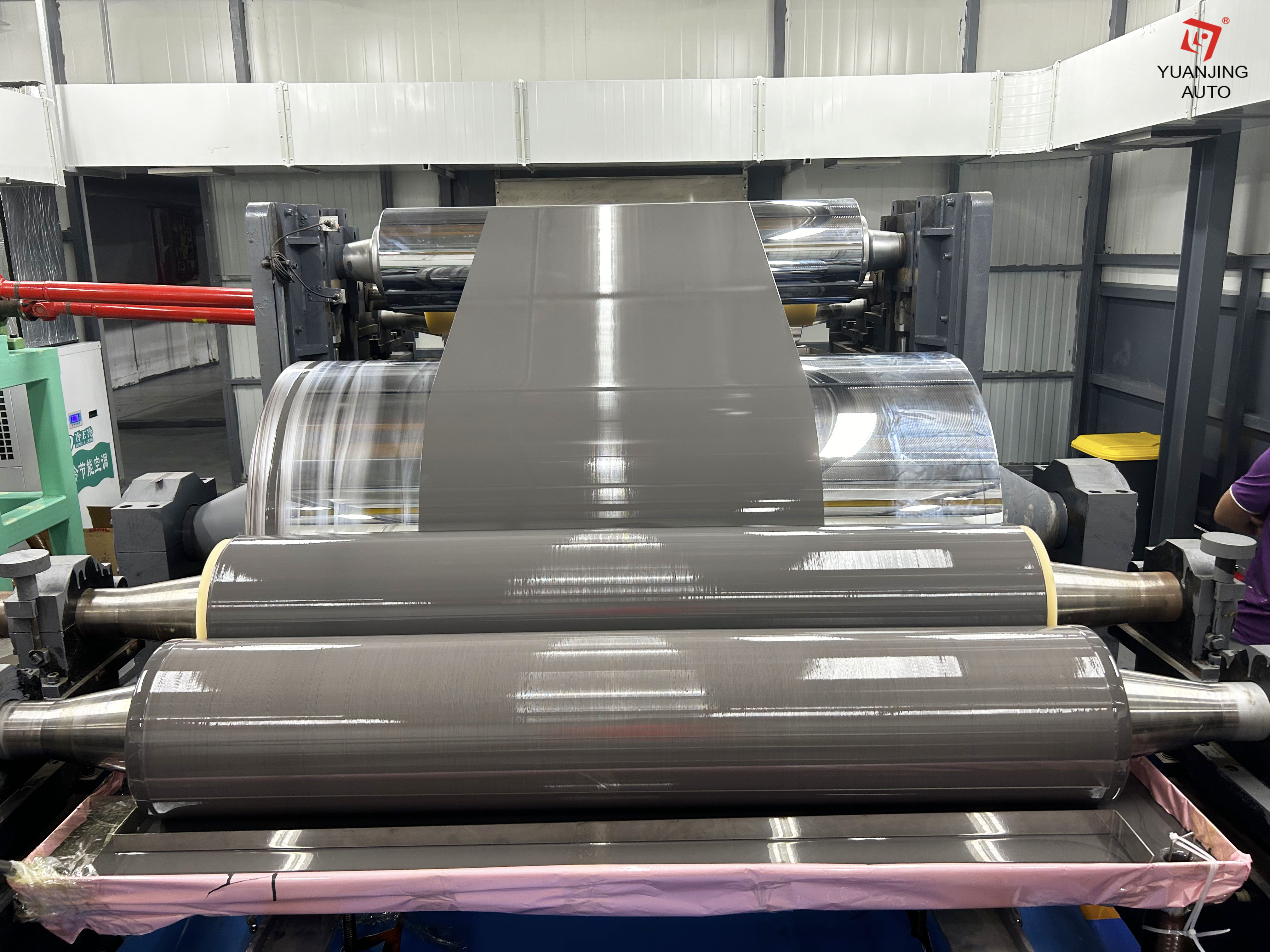

Innovations in Continuous Galvanizing Lines Hot-dip galvanized and alloy galvanized steel coils have excellent performance and ideal corrosion resistance, forming and coating comprehensive properties. To meet the diverse needs of our valued...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Continuous Hot Dip Galvanization Production Line The fully automatic continuous galvanizing line supports manual and automatic control of the steel coil trolley transportation. In automatic mode, it is rich and powerful. During the automatic...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Automatic Continuous Zinc Steel Galvanization Production Line The line speed of the transmission device of the fully automatic continuous galvanizing line is precisely controlled by a high-precision speed control system to keep it consistent. It...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Steel Hot Dipped Zinc Galvanization Production Line The system of the fully automatic continuous galvanizing line consists of three parts: the entry section, the process section, and the exit section. The entry looper of the galvanizing line can...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Continuous Galvanization Production Line for Hot Dip Steel

The EPC system of the coiler of the continuous galvanizing production line adopts sine wave, cosine wave, and trapezoidal wave control technology, which can improve the high-quality...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Automatic Steel Galvanization Production Line The continuous galvanizing line mainly coats a layer of zinc or zinc/aluminum on the surface of the steel strip to improve corrosion resistance. It can provide a stable and safe production environment...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Galvanizing Production Line for Steel The fully automatic continuous galvanizing line reduces the defects caused by inconsistent tension.

The galvanizing tank of the galvanizing line is filled with molten zinc liquid, and the steel is immersed in...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Steel Coil Hot Galvanization Production Line Each set of S-rollers in the galvanizing line system uses a control method (tension type or speed type) that precisely matches the function. In the links where precise tension control is required before...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Automatic Continuous Zinc Plating Galvanization Line Hot dip galvanizing line system functions:

The inlet steel coil of the galvanizing line provides manual and automatic control conveyor chains, which can automatically unbundle, automatically...

-

Min. Order:1 Piece/Pieces

Transportation:Ocean

Steel Coil Galvanized Production Line

Continuous galvanizing line is an industrial equipment used for constant hot-dip galvanizing of metal strips (such as steel plates and steel strips), which is widely used in the automobile, construction, home...

automatic galvanization production line

1 1

What is galvanizing production line?

It is mainly used to coat a layer of zinc on the surface of steel to improve its corrosion resistance. Galvanizing usually has two methods: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing is to immerse the steel in molten zinc, while electro-galvanizing is to deposit zinc by electrolysis.

|

2 2

How long is the product cycle

45-60 days at the earliest

|

3 3

How is the production process controlled?

Our entire production line is meticulously managed by a PLC system, which ensures consistent tension and precise speed throughout the manufacturing process. This guarantees that we meet the highest quality standards for our products.

|

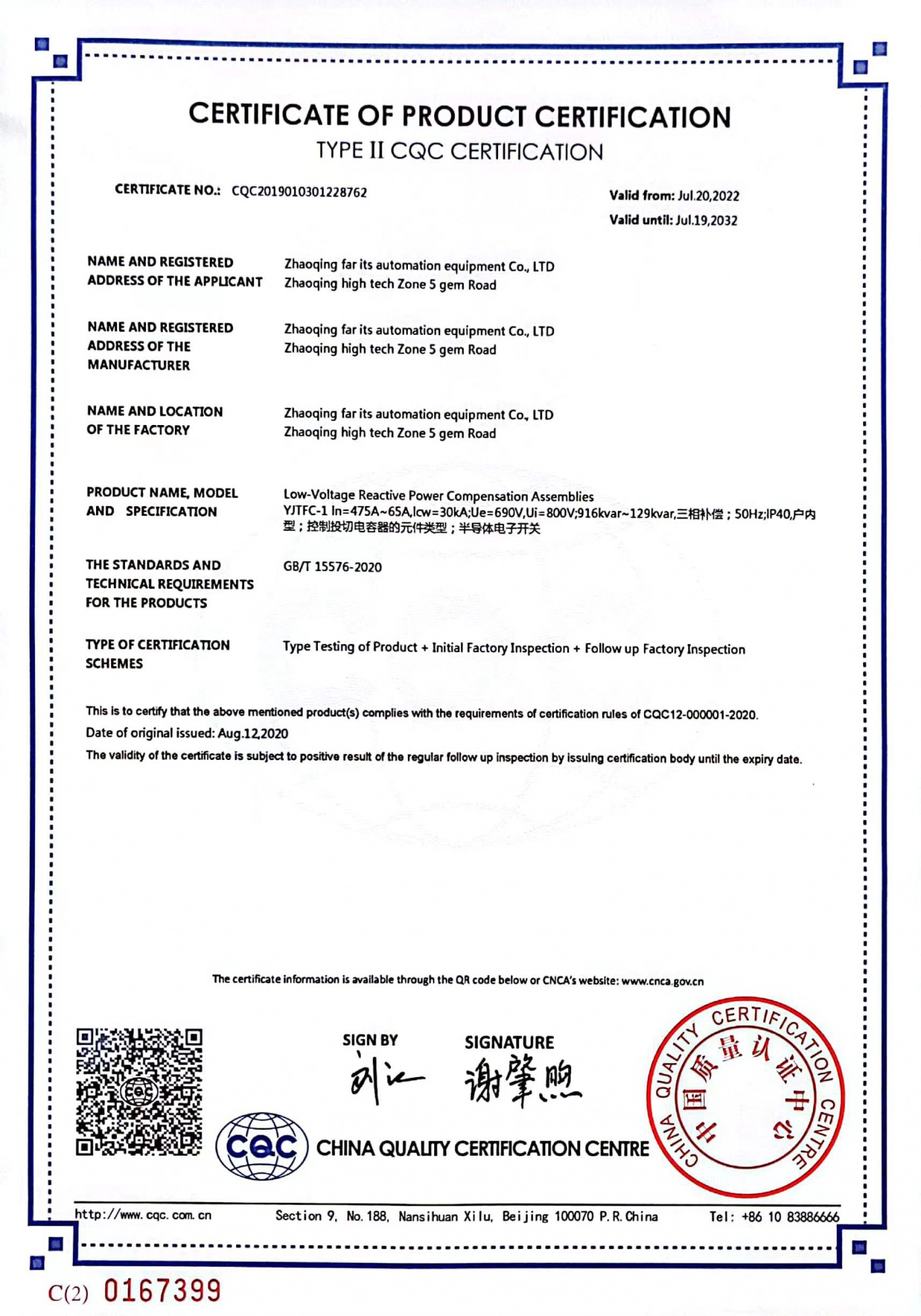

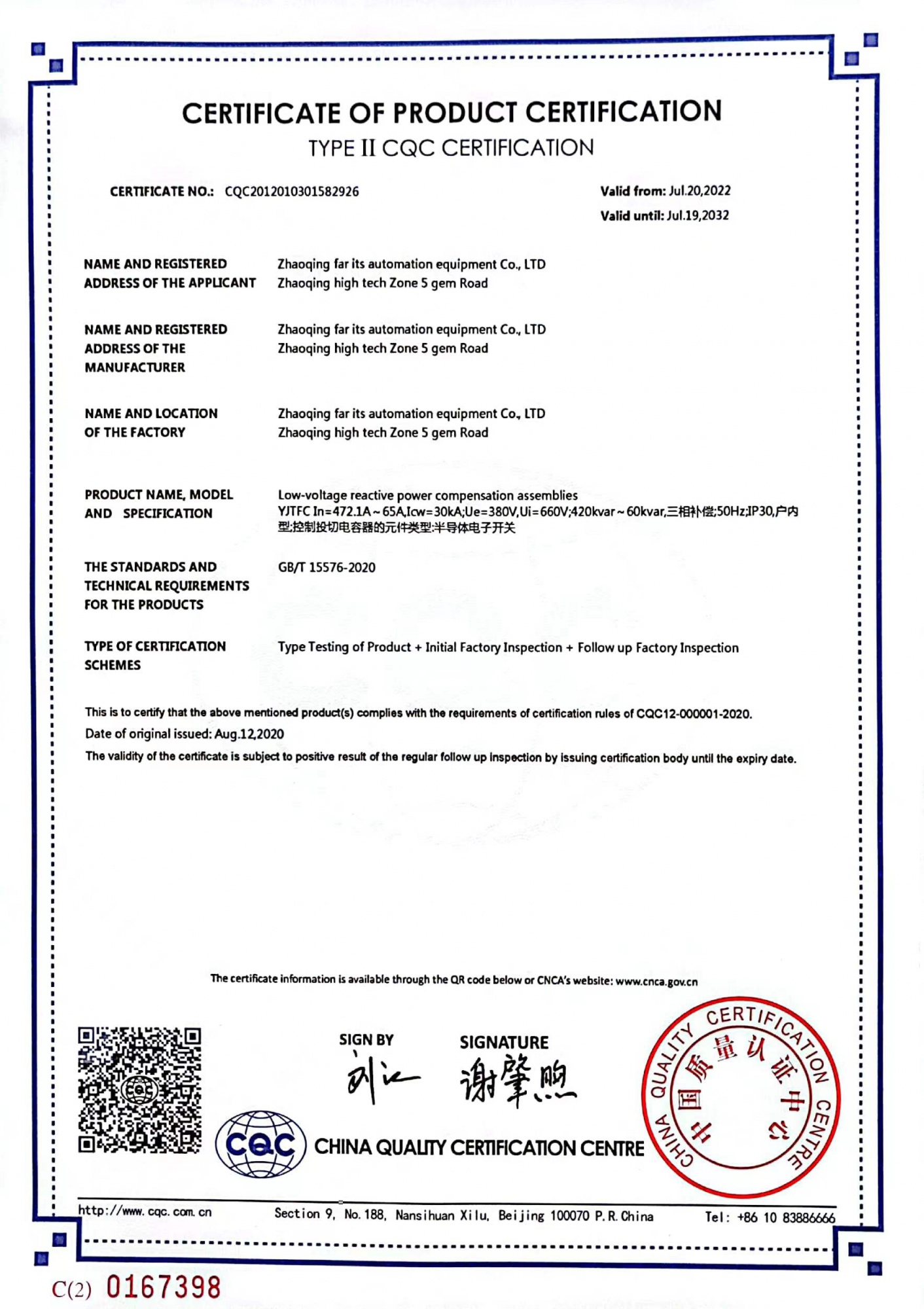

QUALIFICATIONS AND HONORS

Quality management certificate

1

1

3

3